Ven Vs Bol: The Unseen Clash of Traditional Craftsmanship and Modern Innovation

Ven Vs Bol: The Unseen Clash of Traditional Craftsmanship and Modern Innovation

In the evolving landscape of traditional craftsmanship and industrial manufacturing, the battle between Ven Vs Bol weighs heavily on industries ranging from woodworking to metal forming. While Ven brands represent the precision, heritage, and artisanal values embedded in handcrafted tools, Bol embodies the efficiency, consistency, and technological edge of modern machine production. This article demystifies the core differences, performance metrics, and real-world applications of Ven versus Bol, revealing not just a contest of machines—but a reflection of shifting paradigms in production philosophy and value.

## Origins and Philosophy: Heritage Meets High Tech The story of Ven began centuries ago in artisan workshops, where hand tools were shaped by master craftsmen using wood, iron, and intuition. Ven products — often handheld or minimally mechanized — remain rooted in tactile mastery, emphasizing control, balance, and durability forged through generations. As one former smith noted, “Ven isn’t about speed; it’s about the soul of the craft.” In contrast, Bol emerged during the industrial revolution and accelerated through the digital age, symbolizing automation, repeatable precision, and scalable production.

Bol-based machines prioritize consistency, reducing human variability through advanced engineering, sensors, and computerized controls. The philosophy shifts from uniqueness forged per piece to reliability at voltage—millions of identical parts produced with millimeter accuracy. > “Bol machines don’t just make tools; they make systems,” says Dr.

Elena Marquis, a production technology expert at Munich Institute of Advanced Manufacturing. “They’re the backbone of smart factories where predictability drives entire supply chains.” ### Craftsmanship and Precision: Human Touch vs Mechanical Perfection When evaluating Ven and Bol tools, precision defines the first critical divide. Ven tools, though designed for ergonomics and user control, inherently rely on manual operation.

This introduces subtle human factors—slight variations in grip, force, and motion—that challenge ultra-fine tolerances often required in aerospace, fine woodworking, and decorative metal arts. Conversely, Bol machines deploy servo-controlled motors, laser-guided systems, and real-time feedback loops. With tolerances often measured in microns, these machines achieve levels of consistency unattainable by hand.

This precision enables mass customization, where each piece meets exact specifications without manual retraining. - **Ven Tools**: Hand-assembled, variable force, subjective fit; ideal for skilled artisans and low-volume bespoke work. - **Bol Machines**: Factory-calibrated, programmable, repeatable variance near zero; suited for high-volume, error-sensitive production.

Notable impact: Artisans using Ven report greater sensory feedback and expressive control, while industrial operators cite reduced error rates and consistent part quality with Bol systems. ### Durability and Maintenance: The Cost of Complexity Durability forms another axis of comparison. Ven hand tools typically consist of simpler mechanical systems—levers, springs, and bearings—made from robust, high-grade steel.

Their open design facilitates easy repair, with many components replaceable by non-specialists. This fosters longevity when well cared for, especially in rugged field environments. Bol machines, however, integrate complex electronics, embedded software, and servo mechanisms.

While this enhances performance, it also increases susceptibility to electrical faults, sensor drift, and software glitches. Maintenance demands specialized technicians, precise calibration cycles, and regular firmware updates to sustain peak operation. Still, the trade-off is significant: Bol systems often feature self-diagnostic capabilities, predictive maintenance alerts, and lifecycle analytics via IoT connectivity—features that reduce downtime in continuous production settings.

> “Maintenance for Ven is skill-based, quick, and local; for Bol it’s data-driven, preventive, and global,” observes hardware engineering analyst Rajiv Desai. “Both require care, but in fundamentally different ways.” ### Ergonomics and Human Factors: Worker Experience Redefined Ergonomics distinguish the user experience. Ven tools, designed with centuries of cumulative refinement, optimize grip angles, weight distribution, and vibration damping—critical in preventing repetitive strain injuries.

Many Ven hand tools have become industry benchmarks for comfort, allowing artisans to work longer hours with minimal fatigue. Bol machines counteract ergonomic strain through automation, reducing repetitive manual motion. Operators oversee clusters of Bol units from station-based workstations or integrated stations, minimizing direct manipulation.

Yet, this shift reduces tactile engagement and can alienate workers accustomed to craft-based roles. Hybrid approaches are emerging: advanced Ven designs now incorporate lightweight composites, anti-vibration handles, and ergonomic contours inspired by modern biomechanics. Some manufacturers blend Ven’s human-centric design philosophy with Bol’s systemic efficiency.

### Cost Dynamics: Craftsmanship vs Scalability Pricing reflects each method’s inherent value. Ven tools command premium costs, justified by craftsmanship, durability, and niche appeal. A high-end Ven chisel or plane may cost ten times a comparable Bol handtool, but for artisans and heritage brands, the investment is perceived as cultural and functional capital.

Bol solutions thrive on economies of scale. While initial machine investment is substantial—ranging from tens of thousands to millions of dollars—they deliver predictable cost per unit at volume. Maintenance contracts and precision reduce waste, improving overall cost-efficiency in mass manufacturing.

> Over 60% of precision engineering firms now allocate more budget to Bol automation systems, balancing craftsmanship demands with global supply needs, according to 2023 industry surveys. ### Real-World Applications: Niche Expertise vs Industrial Dominance In woodworking, Ven tools dominate custom furniture and sculptural detailing, where the artisan’s hand brings character and uniqueness. Master carvers and cabinet makers often swear by Vern Johns or Strathmore Ven blades for their control and grain-hugging precision. Meanwhile, Bol systems power furniture factories, cabinetry plants, and aerospace composites mills—environments where thousands of identical components are essential.

The aerospace sector, for example, relies on Bol-machined titanium brackets with tolerances under 5 microns, impossible to maintain consistently by hand. Metalworking reveals another frontier: welding, machining, and CNC-automated cutting. Here, Bol machines excel in repeatable edge quality and spatial accuracy, while Ven-market tools see niche use in restoration or artisanal metal art, where imperfection tells a story.

> “For mass-produced consumer goods, Bol delivers unmatched stability,” says Sofia Lin, director of production at Nordic Tool Corp. “But when a piece demands artistry, Ven remains irreplaceable.” ### The Human Element: Craftsmanship in a Digital Age Beyond machines, the Ven vs Bol debate reflects a broader tension: the value of human craft versus mechanical perfection. Ven embodies patience, individuality, and intangible skill—monuments to tradition in an accelerating world.

Bol represents progress, scalability, and data-driven excellence, pushing industries toward smarter, faster, and safer production. Yet the most compelling developments lie in convergence. Hybrid workshops now pair expert craftsmen wielding Ven tools with Bol systems for precision backup.

Digital design tools like CAD guide both, enabling artisans to prototype with Ven methods before integrating Bol-optimized manufacturing. This synergy suggests a future where heritage and innovation coexist—not as rivals, but as complements. The true measure is not whose tool wins, but how the sum enhances quality, efficiency, and heritage.

In understanding Ven versus Bol, we do more than compare machines. We witness the evolution of human ingenuity—craft refined by technology, and technology enriched by craft. The clash endures, but from it emerges a richer, more balanced future for creation.

Related Post

Car Game Red: Where Automotive Passion Meets Competitive Fun

Emmual Lewis: The Rising Star Reshaping Modern Music

David Muir’s Hidden Life: The Quiet Strength Behind the ABC Anchor’s Wife

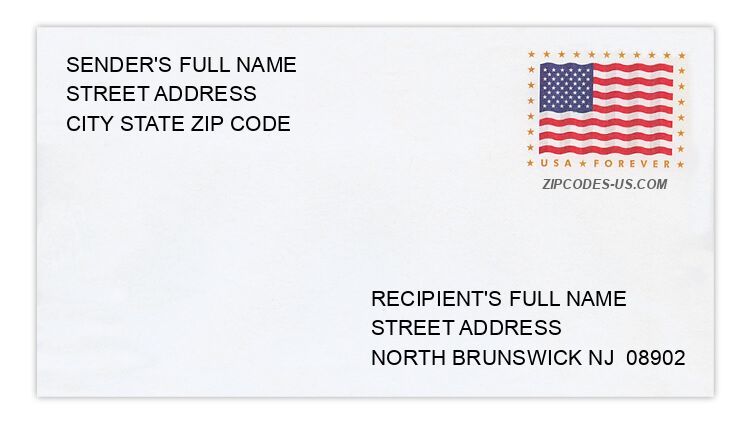

North Brunswick, NJ Zip Codes A Quick Guide to Navigating the County’s Precise Postal Zones