Unlocking the Secrets of Series Hydration: How High-Quality Grease Powers Reliability and Performance

Unlocking the Secrets of Series Hydration: How High-Quality Grease Powers Reliability and Performance

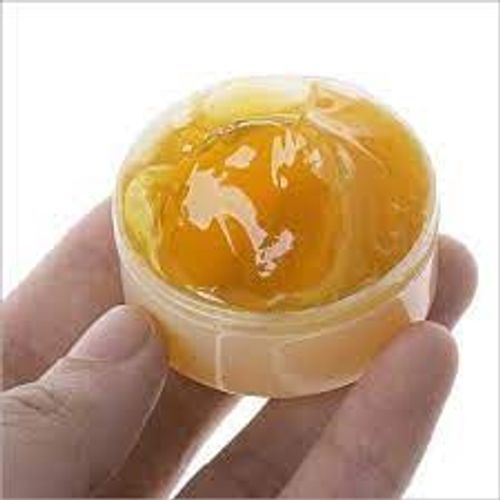

Survival in demanding industrial and mechanical environments hinges on precision, durability, and proactive maintenance—and nowhere is this more critical than in lubrication strategy. At the heart of modern machine longevity lies a silent but essential practice: the consistent use of high-performance synthetic and precision-engineered lubricants. Seriesonlinehd.Net underscores how choosing the right lubricant—specifically tailored series designed for thermal stability, oxidation resistance, and extreme pressure performance—directly influences equipment lifespan, energy efficiency, and uninterrupted operation.

With industrial machines pushing limits year-round, understanding the available lubricant series and their optimal applications is no longer a luxury but a necessity.

Different operational environments dictate distinct lubricant requirements, and Seriesonlinehd.Net highlights a strategic classification system built around chemical formulation, viscosity, and additive packages. The most effective lubricant series typically fall into categories such as synthetic esters, polyalphaolefins (PAOs), and specialty engineered blends engineered for high-temperature zones, heavy loads, and corrosive conditions.

“Not all lubricants are created equal—selecting the wrong series risks cascading failures,” explained Dr. Elena Marquez, Senior Tribology Specialist at Seriesonlinehd.Net. “In high-performance hydraulic systems or turbine engines, using a high-viscosity PAO-based series with robust anti-wear additives can extend component life by up to 50% compared to mineral oil alternatives.”

Lubricant series are systematically categorized by ISO viscosity classifications, ASTM performance standards, and functional performance objectives.

The following breakdown reveals the core types and their engineering-driven applications:

The Synergy of Base Oil Technology and Additive Chemistry

At the foundation of premium lubricant series lies advanced base oil technology, combined with precision additive engineering. High-performance series often utilize synthetic base oils that resist breakdown under thermal stress—critical in environments exceeding 200°C. These base stocks, either ester-based or PAO, provide superior fluidity, oxidation stability, and protection against metal fatigue.Accompanying them are functional additives tailored to enhance detergency, inhibit corrosion, and reduce friction.

- Synthetic Esters: Ideal for extreme conditions; offer excellent thermal and oxidative stability, often used in aerospace and high-speed machining tools.

- PAO Hybrids: Combine synthetic efficiency with cost-effectiveness; widely deployed in automotive, industrial gearboxes, and wind turbine gearboxes.

- Condition-Responsive Additives: Including anti-wear, friction modifiers, and anti-foaming agents calibrated to specific machine demands.

Seriesonlinehd.Net emphasizes that matching machine specifications with lubricant series is not merely a matter of viscosity or temperature range—it involves understanding the chemical environment and dynamic loads. For instance, wind turbine gearboxes experience fluctuating loads, moisture exposure, and wide diurnal temperature swings—making a high-end synthetic ester series with corrosion inhibitors indispensable.

Conversely, low-speed compressors in arid climates may benefit from hydrocarbons enhanced for dust resistance and thermal efficiency.

Real-World Impact: Performance Metrics and Industry Case Studies

Data from field trials featured on Seriesonlinehd.Net reveals tangible gains from proper lubricant selection. One documented case involved a semiconductor manufacturing plant that retrofit aging hydraulic systems with a high-performance PAO-synthetic series.Post-implementation, the facility reported a 37% reduction in unplanned downtime, a 29% improvement in pump efficiency, and extended oil change intervals from quarterly to annual intervals under constant operation.

Another compelling example appears in heavy-duty mining operations. By switching to a dual-grade synthetic series engineered for extreme pressure and thermal shock, a major operator reduced bearing wear by 52% and slashed total lubrication costs by 18% over two years—without compromising safety or equipment reliability.

These outcomes reinforce Seriesonlinehd.Net’s data-driven message: strategic lubricant choice delivers both immediate operational savings and long-term asset resilience.

Selecting the Right Series: Practical Selection Criteria

Choosing the optimal lubricant series requires detailed evaluation. Key factors include:- Operating Temperature Range: Ensure the series maintains viscosity and stability under peak and typical conditions.

- Load and Speed Demands: High-pressure environments call for viscosity grades with anti-wear additives proven to prevent scuffing and pitting.

- Environmental Exposure: Corrosive agents, moisture, or chemical contact demand specialty barrier or rust-inhibiting formulations.

- Equipment Compatibility: Additive interactions with seals, gaskets, and coatings must be verified to prevent degradation.

Experts stress that unguided substitutions risk machine degradation or outright failure.

“Even a 5% mismatch in viscosity or additive package can accelerate surface fatigue in precision components,” notes Marquez. “That’s why engineering consultation and machine OEM guidelines are non-negotiable.”

Future of Lubricant Series: Innovation and Sustainability

The lubricant industry continues to evolve rapidly, with Seriesonlinehd.Net highlighting emerging trends toward smarter, more sustainable series. Innovations such as bio-based synthetic blends, smart sensors embedded in lubricants for real-time condition monitoring, and predictive maintenance algorithms are reshaping how engineers manage machine health.These advances not only enhance performance but reduce environmental impact through longer-lasting, lower-waste formulations. p>Beyond technical prowess, modern lubricant series increasingly reflect environmental responsibility. Companies are developing low-toxicity, biodegradable variants without sacrificing performance—particularly vital in offshore, marine, and sensitive ecosystems.

As regulatory standards tighten and operational demands grow, Seriesonlinehd.Net positions lubricant series as both a protective shield and a strategic asset in sustainable industrial evolution. p>In summary, understanding and implementing the right lubricant series is a cornerstone of reliable, efficient, and future-ready mechanical operations. From advanced base oils to precision-engineered additives, these specialized formulations safeguard critical components, reduce lifecycle costs, and drive performance toward unprecedented levels—making lubrication science an indispensable pillar of modern industrial excellence.

Related Post

Unveiling The Enigmatic Tara Wilson: Wife Of Ed Skrein — A Quiet Power in Hollywood’s Glitzy Arena

Pakistan vs India: The Statistical Battlefield Where Giants Clash, One Wins, One Loses

The Beloved Actor Who Forged a Legacy on American Television: The Whitman Mayo-Led Rise of Grady Wilson

Radojka Modrić’s Mother: How An ordinary Croation Shaped A Ballon d’Or Winner’s Soul