Unlock Enterprise Potential: How Kron 4 Is Revolutionizing Modern Manufacturing with Smart Data Integration

Unlock Enterprise Potential: How Kron 4 Is Revolutionizing Modern Manufacturing with Smart Data Integration

In an era where data drives precision and speed, Kron 4 emerges as a transformative force in industrial operations, empowering manufacturers to harness real-time insights and eliminate inefficiencies. By redefining how production ecosystems interact—connecting shop floor systems with enterprise intelligence—this latest platform software isn’t just an upgrade; it’s a strategic leap forward. From predictive maintenance to seamless supply chain coordination, Kron 4’s advanced architecture delivers measurable gains across performance, safety, and scalability, making it indispensable for competitive manufacturers today.

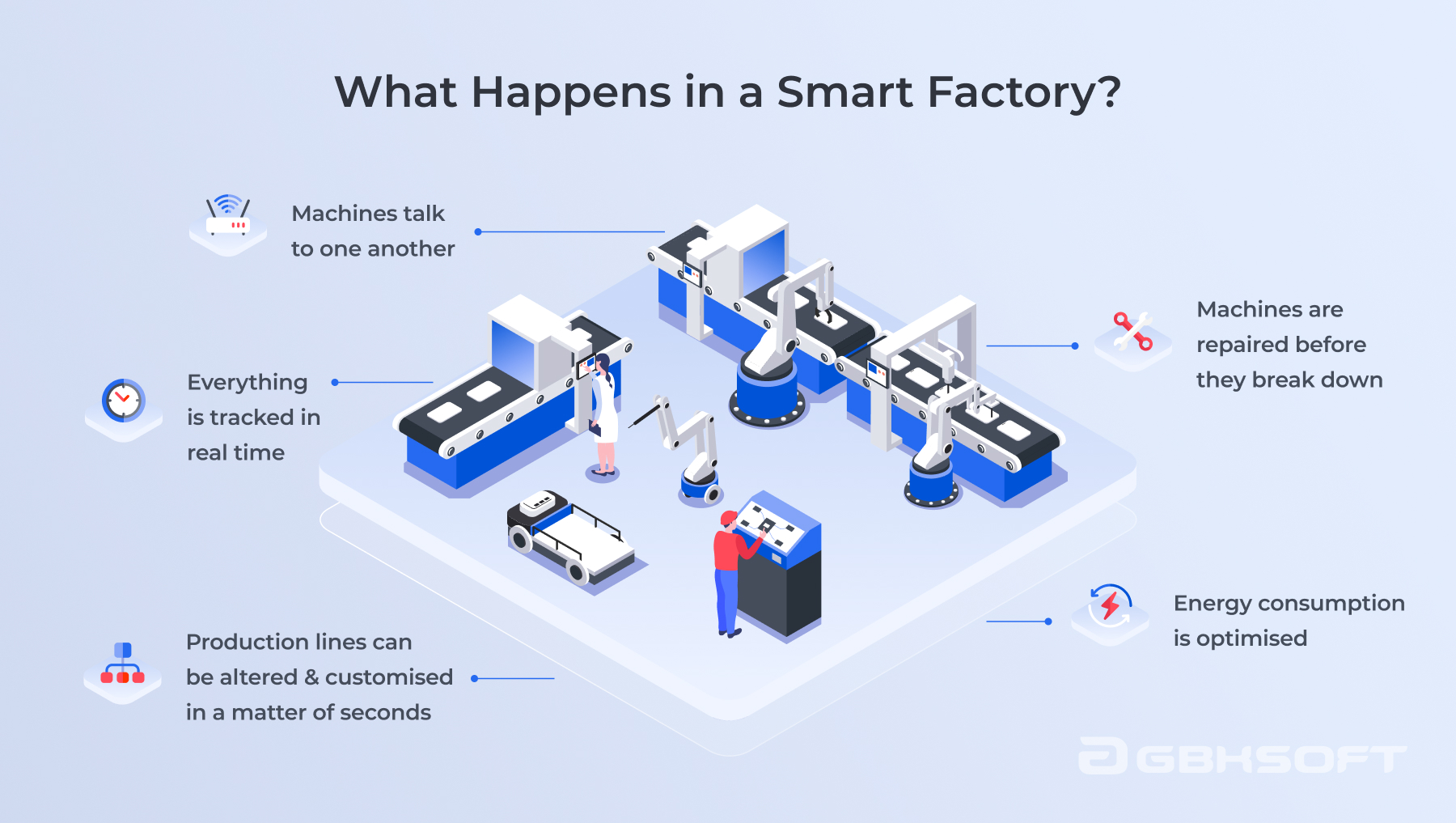

At its core, Kron 4 integrates core functionality from its predecessor while introducing groundbreaking capabilities tailored for the Industry 4.0 landscape. The platform unifies disparate systems—MES, ERP, SCADA—into a single, coherent digital thread. This integration reduces data silos, accelerates decision-making, and ensures consistency across operations.

Chief Technology Officer Elena Marquez describes it as “a unified nerve center where every machine, process, and person speaks the same language.” By eliminating fragmented reporting and manual reconciliation, Kron 4 slashes operational latency and empowers engineers and managers to act faster.

This capability enables proactive interventions—such as automated adjustments to machinery or early fault warnings—minimizing downtime and preserving product quality. Advanced machine learning models embedded within Kron 4 continuously refine predictions and recommendations based on historical and live operational data. For example, predictive maintenance algorithms reduce unplanned downtime by identifying wear patterns before failures occur.

These models consider variables including vibration levels, temperature fluctuations, and energy consumption trends to deliver hyper-accurate failure forecasts. Integrated digital twins amplify Kron 4’s utility by creating dynamic, real-time virtual replicas of physical assets. These digital models simulate entire production lines under varying conditions, allowing operators to test changes, optimize workflows, and validate decisions without disrupting live operations.

As a result, innovation cycles shorten, and process improvements become iterative rather than experimental.

One OEM operator reduced configuration cycles from hours to minutes, dramatically increasing daily throughput. In electronics manufacturing, where precision and yield are paramount, Kron 4’s granular process monitoring ensures consistent quality at scale. Real-time deviation alerts help engineers correct soldering or assembly errors before they propagate through the line.

This precision reduces waste, boosts first-pass yield, and strengthens compliance with stringent industry standards. Heavy equipment producers leverage Kron 4’s supply chain integration to align production schedules with material availability. By synchronizing shop floor activity with supplier lead times, companies have lowered inventory holding costs by 25% while maintaining just-in-time delivery reliability.

These cross-functional synergies illustrate Kron 4’s role not just as a monitoring tool, but as a strategic orchestrator of enterprise-wide efficiency.

Operators benefit from visual health indicators and step-by-step guidance during maintenance, reducing reliance on extensive documentation. Managers access aggregated KPIs that highlight trends, risks, and opportunities in seconds, enabling timely strategic adjustments. “Kron 4 doesn’t just deliver data—it makes it meaningful,” states operations director James Tran.

“By grounding complex analytics in clear visuals and actionable insights, it empowers every level of the organization to contribute to continuous improvement.” This user-first philosophy lowers training barriers, accelerates adoption, and fosters a data-driven culture from shop floor to C-suite.

This adaptability ensures manufacturers can deploy new capabilities without costly system overhauls, future-proofing investments in a rapidly changing technological landscape. Moreover, Kron 4 integrates smoothly with public and private cloud environments, supporting hybrid deployments that balance security, latency, and scalability. For global enterprises managing distributed operations, this flexibility enables centralized oversight while respecting local infrastructure needs.

For data-sensitive deployments, on-premise hosting options ensure compliance and control. The platform’s open ecosystem further encourages innovation through APIs and third-party integrations, allowing companies to extend Kron 4’s functionality with industry-specific tools—whether quality control systems, energy management software, or workforce planning platforms.

In a recent assessment, Gartner highlighted Kron’s “unmatched

Related Post

Ashley Zavala Kron 4: A Rising Star in Sports Biometrics and Human Performance

Fluminense vs Internacional: The Frost-Kissed Clash of Brazilian Flags in Predictive Soccer Analytics

Who Is Freddie Highmore Married To? The Private Life of the Rising Star