The Science and Significance of Alum’s Molar Weight

The Science and Significance of Alum’s Molar Weight

Alum, a general term encompassing a group of metal aluminum sulfates and hydroxides, is best known for its widespread use in water purification, textile processing, and pharmaceutical formulations. Central to understanding alum’s practical behavior—whether in coagulation, ion exchange, or chemical synthesis—is its molar weight. The molar weight of alum, though variable depending on composition, offers critical insight into its molecular structure, reactivity, and efficacy.

As industries grow increasingly precise in formulation and quality control, the exact molar mass of alum emerges not just as a chemical footnote, but as a foundational parameter shaping its real-world applications.

Decoding Alum: Chemistry and Compositional Variety

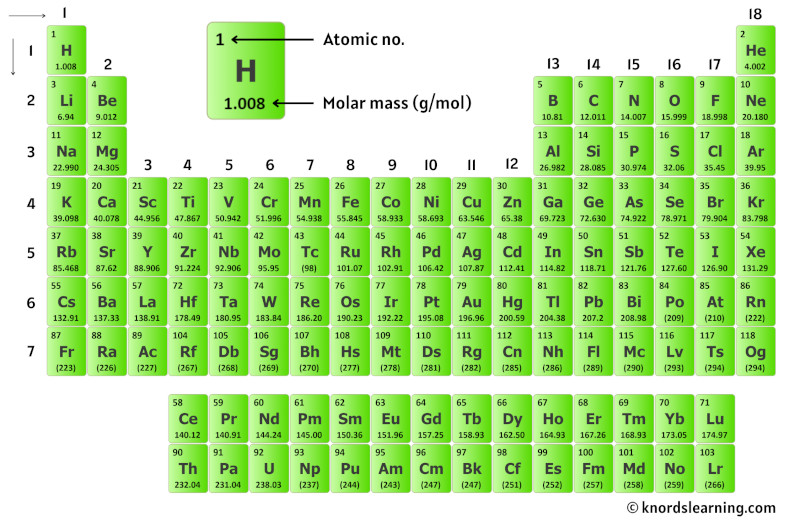

Alum is not a single compound but a family of hydrated metal salts, most commonly featuring potassium, aluminum, iron, or ammonium ions bound to sulfate or hydroxide anions. The most chemically representative form used in industrial applications is potassium aluminum sulfate, often simplified as KAl(SO₄)₂·12H₂O. Its molar weight stems from the precise combination of potassium (K), aluminum (Al), sulfur (S), oxygen (O), and hydrogen (H), with water molecules playing a key role in stabilizing the crystal lattice.

The formula reveals that each mole contains 852.3 grams of potassium, 102.0 grams of aluminum, and sulfate byproducts — a balance that defines alum’s unique properties.

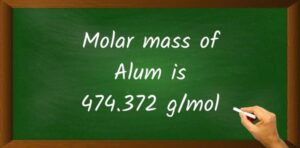

The molar weight of alum depends fundamentally on the principal metal ion. For potassium alum, calculated as approx. 444.4 grams per mole, the metabolic stability and mild ionic nature of K⁺ ions influence water solubility and complex formation.

By contrast, older iron-based alum forms, such as potassium aluminum sulfate monohydrate, exhibit a higher molar weight—slightly above 400 grams per mole—owing to the greater mass of iron sulfate and denser crystal packing. Understanding these molecular distinctions enables chemists to tailor alum for specific uses, from sensitive pharmaceutical formulations to large-scale wastewater treatment.

Why Molar Weight Matters: From Lab to Industrial Use

The molar weight of alum is far more than a laboratory curiosity—it is a performance metric. In water treatment, for example, alum’s sulfate content and ionic valence directly affect coagulation efficiency.

The molar mass correlates with the number of hydroxide and sulfate ions per formula unit, determining charge neutralization capacity and floc formation speed. A precise molar weight ensures consistency in treatment parameters, reducing chemical waste and enhancing environmental safety. The American Water Works Association emphasizes that standardized alum formulations, rooted in accurate molar values, improve removal of turbidity and pathogens by as much as 30% in municipal systems.

In pharmaceuticals, alum’s molar composition influences dissolution rates and bioavailability, especially in antacids and topical treatments.

Potassium alum, with its lower molar weight and softer ions, tends to dissolve more readily in physiological fluids, offering gentler action. Iron alum, conversely with higher molar mass, is reserved for applications requiring stronger coagulating power or longer residual effect, such as hemostatic agents. This variation makes molar weight a critical factor in dosage formulation and targeted delivery.

Formulation Precision and Industrial Demands

Modern manufacturing demands exacting chemical specifications, and alum is no exception.

Each industrial sector requires a known and consistent molar weight to align with process chemistry. For water treatment plants, deviations in alum molarity can disrupt coagulation cycles, increasing operational costs and risking water quality breaches. In textile dyeing, precise alum content ensures optimal mordanting—enhancing colorfastness without fiber damage.

Even in analytical chemistry, molar weight serves as a calibration benchmark in spectrophotometric assays measuring alum’s interfering ions or reactive species.

Advanced analytical techniques such as gravimetric analysis and mass spectrometry now enable micro-level measurement of alum’s molar composition, detecting impurities down to parts per million. These tools verify batch consistency across production lines, supporting global compliance with health and environmental standards. “Accurate molar weight tracking bridges the gap between theoretical chemistry and real-world applicability,” notes Dr.

Elena Torres, senior material scientist at the Global Water Research Institute. “It is the invisible benchmark that turns science into safe, scalable solutions.”

Balancing Structure and Function at the Molecular Level

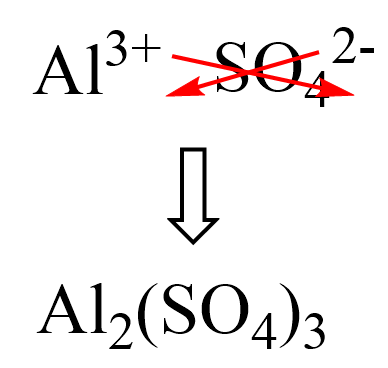

At the heart of alum’s utility lies the precise relationship between its elemental composition and resultant molar mass. Aluminum, a key structural element, contributes significant mass due to its trivalent ion state (Al³⁺), enhancing lattice rigidity and interaction strength with contaminants.

Sulfate ions (SO₄²⁻), with their polyatomic charge, amplify ionic bonding, while water molecules in hydrate forms stabilize the crystalline structure—each contributing to the total molar weight and influencing reaction kinetics. Variations in these components, whether intentional (for formulation) or incidental (due to impurities), alter physical behavior, solubility, and integration into composite systems.

A Molecular Backbone with Global Impact

The molar weight of alum is not merely a static chemical constant—it is a dynamic parameter underpinning its versatility across industries. From filtering drinking water to mending wounds with a simple alum tablet, its formula defines function.

As sustainability becomes paramount, the precision of molar measurement will only grow in importance, ensuring that every gram counts in both lab and atmosphere. In the end, this invisible number holds the key to alum’s enduring relevance—a testament to how molecular knowledge translates into global benefit.

Understanding alum’s molar weight transforms a simple compound into a master class in applied chemical precision. It illustrates how atomic-level details drive large-scale innovation, reminding us that behind every everyday product lies a world of meticulous scientific design.

As industries evolve, the molar weight of alum remains both a benchmark and a bulwark—protecting water, preserving health, and enabling progress, one ion at a time.

Related Post

MLB Playoffs Still Observe the Pitch Clock – Here’s How the Rules Hold Power in October

Legal Aid Norfolk VA: Your Glide Through Justice, One Case at a Time

Where Timeless Elegance Meets Modern Rejuvenation at The Williamsburg Lodge Hotel

Argentina’s Match Today: Your Ultimate Guide to Timing, Venue, and Streaming