The Art Of Diamond Cutting: A Comprehensive Guide

The Art Of Diamond Cutting: A Comprehensive Guide

Turning raw diamond crystals into brilliant, fire-firening masterpieces is far more than a craft—it is a precise science, a timeless tradition, and a vital economic force in the global gem trade. The art of diamond cutting transcends mere craftsmanship, embodying physics, geometry, and centuries of meticulous refinement. This comprehensive guide explores how modern and traditional diamond cutting transforms rough stones into awe-inspiring gemstones that capture light, amplify brilliance, and evoke lasting beauty.

At the heart of diamond cutting lies the pursuit of maximal light interaction—how each faceted surface refracts, reflects, and disperses light to create the signature sparkle that gives diamonds their legendary allure. The process begins not with destruction, but with vision: skilled cutters analyze each rough diamond’s inclusions, crystal structure, and natural proportions to determine the optimal plan for enhancing clarity, color, and fire. As renowned gemologist Fred Huang notes, “Every diamond tells a story; cutting is how we reveal its voice.”

From Rough Stone to Radiant Gem: The Cutting Process

The transformation from unpolished rough to dazzling gem unfolds through a sequence of scientifically calibrated steps.Each phase balances technical precision with artistic judgment. **1. Inspection and Planning** Before the first cut, diamond analysts conduct detailed scrutiny using advanced imaging technologies—x-ray tomography, laser scanning, and spectrographic analysis.

These tools reveal internal flaws, crystal orientation, and stress points that influence cutting strategy. “Cutting is as much about what you avoid as what you reveal,” explains master cutter Elena Petrova. This phase determines facet layout, angle precision, and weight retention policies such as retention limits—typically preserving 50–60% of the rough’s original mass to maintain value.

**2. Cleaving and Sawing: Precision Foundation** Once the plan is set, the rough diamond undergoes cleaving or laser-assisted sawing. Cleaving—striking along natural crystal planes—preserves structural integrity and minimizes damage.

Modern laser cutting and wire sawing have revolutionized efficiency, enabling cleaner, more accurate sections with minimal material loss. These technologies reduce human error and allow for complex cuts previously unattainable by hand. **3.

Bruting, Faceting, and Angle Mastery** The cutter then shapes the diamond using a series of precisely angled facets—usually 58 in the classic round brilliant—each calculated to maximize light return. The crown angles, running from 34° to 35.5°, and the pavilion angles between 40° and 41° work together to direct light deep into the stone before executing a brilliant return. As master cutter Andreas Zimmermann emphasizes, “Mortality of light is the diamond’s soul—angles must guide it like a conductor leading an orchestra.” Facet alignment remains paramount.

Even minor deviations reduce brilliance, while symmetrical, uniform faceting amplifies dispersion—the splitting of white light into spectral hues. Quality control at each step ensures consistency, traceability, and enduring value.

The Science Behind Sparkle: Optics and Light Performance

A diamond’s fire does not emerge arbitrarily—it results from deliberate optical engineering.Light enters through the crown, reflects off the triple fluorescence (parent, analytical, and right-angle reflexes), and exits via well-polished facets carrying brilliance into the viewer’s eye. Key optical principles include: - **Total Internal Reflection (TIR):** Light bounces completely within the diamond when angles preserve its path; poor facets scatter it prematurely. - **Refractive Index:** Over 2.4, diamonds bend light significantly more than any other mineral, amplifying brilliance.

- **Dispersion:** The separation of white light into spectral colors—achieved through precise crown angles, responsible for the rainbow flashes known as fire. Master cutters study these phenomena alongside mathematical models to optimize cut depth, antefacet precision, and crown thickness. Even the slope of a single facet can influence how light travels through the stone—underscoring the fusion of physics and art.

Traditional Techniques Meets Modern Technology

Diamond cutting has evolved from centuries-old manual methods to a high-tech discipline combining heritage skill with cutting-edge automation. In workshops from Antwerp to Mumbai, master cutters still rely on hand-held turning tools and specialized lamps for visual assessment. Yet, automation is reshaping production: computer numerical control (CNC) machines and machine learning algorithms now assist in facet templating, defect mapping, and sorting—enhancing consistency and reducing waste.Despite technological advances, human expertise remains irreplaceable. The “eye” of the cutter—developed over years of practice—detects subtle nuances machines cannot assess. “Technology extends capability,” says Licht & More expert Maria Klaus, “but intuition and craft remain the diamond’s guiding heart.”

Industry Significance and Ethical Considerations

Diamond cutting is a global enterprise underpinning billions in trade and employment.Major hubs—Antwerp, Tel Aviv, and Dubai—drive innovation and maintain strict quality standards. Recent growth has also intensified focus on ethical sourcing through initiatives like the Kimberley Process and emerging traceability technologies. Ethical cutting practices ensure transparency from mine to market, addressing concerns about conflict diamonds and labor equity.

“Ethics and excellence walk hand in hand,” asserts Francesca Moretti, head of sustainable sourcing at GemCert. The art of diamond cutting, therefore, extends beyond beauty—it anchors trust, responsibility, and global standards vital to the industry’s future.

Mastering the Craft: Training and Competence

Becoming a master diamond cutter demands rigorous education and years of disciplined practice.Top training programs blend theoretical optics, crystallography, and gemology with hands-on apprenticeships under seasoned instructors. Programs often include advanced courses in laser cutting, diamond grading (via the 4Cs), and CAD modeling for innovative designs. Competitions such as the Master Cutter’s Challenge test precision, creativity, and technical mastery under controlled, high-stakes conditions.

These arenas foster continuous innovation, challenging cutters to refine angles, improve light return, and push the limits of craftsmanship.

Future Frontiers: Innovation and Sustainability

Emerging technologies promise to redefine diamond cutting. AI-driven predictive modeling anticipates light behavior with unprecedented accuracy, while laser ablation enables micro-level adjustments once impossible by hand.Concurrently, sustainability initiatives are reshaping production: energy-efficient cutting machines, water recycling, and blockchain traceability ensure minimal environmental impact. “Future cutting is smarter, cleaner, and more intentional,” predicts Dr. Lina Soh, Director of Innovation at the Gemological Institute of America.

“We’re not just cutting stones—we’re engineering brilliance responsibly.”

Final Reflections: The Art As Legacy

The art of diamond cutting endures as a bridge between nature’s raw gift and human creativity. It transforms rough, inconspicuous crystals into luminous symbols of beauty, commitment, and achievement. Every facet reflects not just light—but centuries of tradition, technical mastery, and ethical intention.As tools evolve and markets expand, the essence remains unchanged: the careful dance of light, angle, and precision creates not just jewels, but legacies. In mastering this ancient art, cutters ensure diamonds continue to inspire awe—one brilliant cut at a time.

Related Post

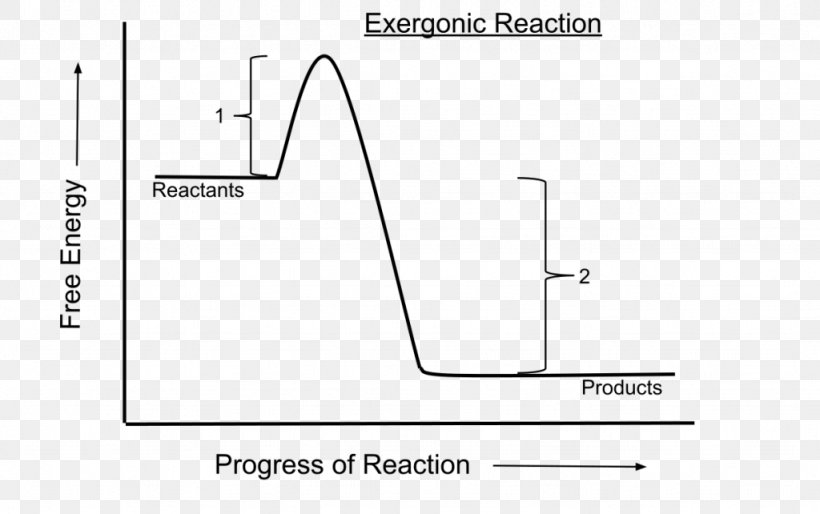

Exergonic Energy: Harnessing the Power of Spontaneous Energy Release

Samuel Jackson’s $7 Billion Earnings: How One Actor Conquered Hollywood—and Valued Independence

Cody Bellinger’s Marriage Under the Spotlight: A Deep Dive Into What Shaped This Power Couple’s Relationship

On October 23, the Cosmic Candlestick Signals Opportunity: Decoding the October 23 Zodiac Influence

-p-500.png)