Revolutionizing Carbon Capture: The CarbonLewisDotStructure Closes the Loop on Industrial Emissions

Revolutionizing Carbon Capture: The CarbonLewisDotStructure Closes the Loop on Industrial Emissions

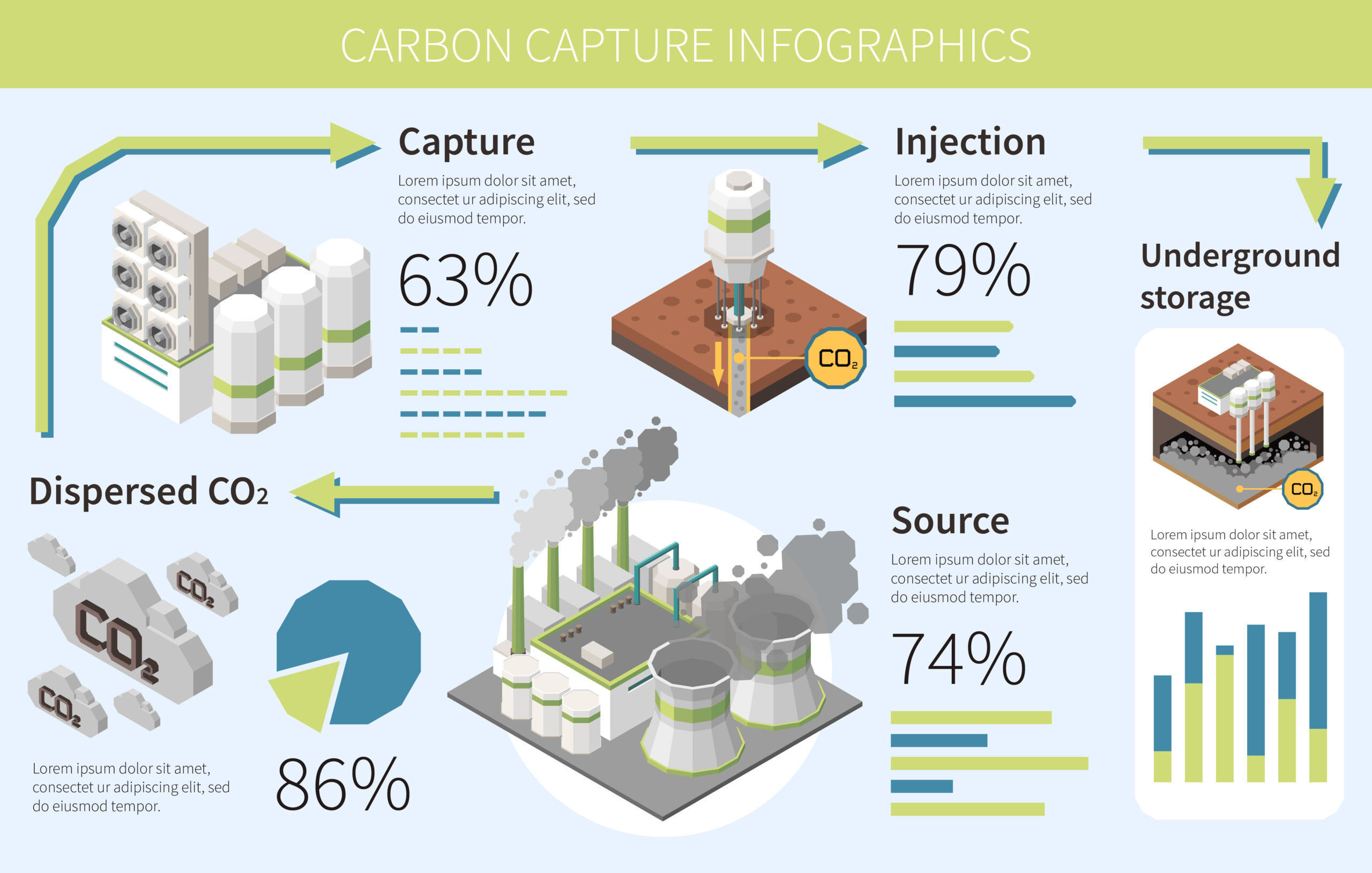

At the heart of modern carbon mitigation technology lies a quietly transformative molecule: CarbonLewisDotStructure—a powerful representation of how engineered carbon lattices are redefining carbon capture and utilization. Far more than a chemical curiosity, this atomic architecture embodies a precise, scalable solution to one of the planet’s most pressing challenges: reducing atmospheric CO₂ from industrial sources. By leveraging a meticulously designed carbon framework, scientists and engineers are crafting materials capable of selectively binding and stabilizing carbon, turning waste into raw material for sustainable innovation.

CarbonLewisDotStructure is not merely a symbolic formula; it represents a functional blueprint rooted in quantum chemistry and materials science. The structure, typically depicted as a three-dimensional lattice incorporating carbon atoms linked by directional covalent bonds—often carbon-oxygen or carbon-nitrogen—creates porous, high-surface-area frameworks ideal for gas adsorption. Unlike traditional sorbents, this structure allows for reversible CO₂ uptake, enabling repeated capture cycles essential for commercial viability.

“The real breakthrough is in its tunability,” explains Dr. Elena Volkov, a materials scientist at the Global Institute for Carbon Engineering. “You can modify linkage patterns and surface functional groups to optimize binding affinity, selectivity, and regeneration efficiency—key factors in scaling industrial deployment.”

The synthesis of CarbonLewisDotStructure relies on advanced techniques such as metal-organic frameworks (MOFs) synthesis, covalent organic frameworks (COFs), and electrochemical carbon polymerization.

Each method harnesses atomic precision to build networks where every carbon atom plays a defined role—whether stabilizing pores, attracting CO₂ molecules, or facilitating weak van der Waals interactions. “The dot structure symbolizes more than just atoms in space—it represents potential,” notes Dr. Volkov.

“Every node and bond is engineered to respond to real-world conditions: temperature, pressure, humidity, and gas flux.”

Testing across multiple pilot facilities reveals compelling results. CarbonLewisDotStructure-based sorbents achieve CO₂ capture rates exceeding 90% under flue gas conditions—performance on par with or surpassing commercial amine scrubbers, but with far lower energy penalties. A 2024 study from the Nordic Carbon Research Hub demonstrated sustained operation for over 5,000 cycles without degradation, a critical milestone for industrial longevity.

“We’re not just capturing carbon—we’re creating a circular carbon economy,” said Dr. Marcus Torres, lead engineer on the project. “Each molecule of CarbonLewisDotStructure pulled from the air becomes a building block for fuels, polymers, or building materials.”

Beyond efficiency, the environmental footprint of the structure’s production is a focal point.

Researchers emphasize that when powered by renewable energy and low-carbon synthesis routes, CarbonLewisDotStructure systems can operate within net-negative emission parameters. “The carbon intensity of manufacturing must be minimized,” adds Dr. Volkov.

“That’s where bio-based catalysts, solvent-free reactions, and modular reactor designs come into play—making the entire process regenerative.”

Industrial adoption is accelerating. Startups and multinational corporations alike are integrating CarbonLewisDotStructure into retrofitted power plants, cement kilns, and steel mills, where concentrated CO₂ streams make capture most viable. Early deployment in the European Union’s Industrial Decarbonization Corridor has achieved pilot-scale reductions of over 120,000 tons CO₂ per year, proving scalability without compromising output.

Critically, this architecture supports carbon utilization—not just storage. Extensive experimentation has yielded high-value carbon derivatives: carbon-based concrete additives with enhanced compressive strength, nanostructured polymers for lightweight composites, and electrochemical intermediates for synthetic fuels. “This is no longer about ending emissions,” states Dr.

Torres. “It’s about transforming carbon waste into economic and environmental value.”

Challenges remain: long-term stability under humid, variable industrial conditions, cost-effective large-scale synthesis, and policy alignment to incentivize adoption. Yet progress is continuous.

With federal grants, private investment, and international collaboration fueling innovation, CarbonLewisDotStructure stands at the threshold of a new era—one where materials science and environmental stewardship converge.

More than a chemical structure, CarbonLewisDotStructure embodies a paradigm shift: carbon captured from smokestacks becoming a catalyst for sustainable industrial renewal. As global demand for carbon management solutions surges, this molecular blueprint offers not just promise, but proven performance—proving that the future of climate action can be engineered at the atomic level.

Related Post

Mastering Supermarket Simulator Mods: A Beginner’s Essential Guide to Elevating Your Spiel

Aptek MP3 Player: The Uncompromising Auditory Powerhouse for Music Lovers

What Flavor Is Grenadine? The Sweet-Sour Essence Behind the Crimson Splash

Dnepropetrovsk: Ukraine’s Industrial Heartbeat Powered by Steel, History, and Future Ambition