Mt125 Loose Gear: Unmasking the Hidden Causes of Drivetrain Complaints

Mt125 Loose Gear: Unmasking the Hidden Causes of Drivetrain Complaints

When your machinery sputters unexpectedly or driveloss manifests in the form of misalignment, vibration, or grinding, the Mt125 Loose Gear phenomenon often lies at the heart of the issue. Known in engineering circles as a critical failure mode affecting gear trains, a loose Mt125 component compromises precision and reliability, demanding immediate attention. Passed through decades of industrial use and mechanical design, the Mt125 Loose Gear is far more than a simple wear point—it represents a convergence of wear dynamics, alignment tolerances, and lubrication integrity.

Understanding its mechanics unlocks pathways to prevention, repair, and performance optimization across diverse mechanical systems.

The Anatomy of the Mt125 Loose Gear System

The Mt125 Loose Gear refers to a standardized gear assembly—typically measuring 125mm in key operational dimensions—susceptible to looseness at critical interfaces such as shaft coupling, bearing interface, or gear mesh points. At its core, the assembly relies on precise preload within bearings and clamping forces to maintain engagement integrity.When these forces degrade due to fatigue, improper installation, or material creep, the gear loses positional stability, resulting in what engineers describe as “operational sloppiness.” Primary Failure Points Include: - Bearing preload deviation causing axial play - Fatigue-induced tooth tip wear at mesh contact zones - Material deformation in spline interfaces under sustained torque - Misalignment from improper assembly or foundation settlement Key Components Vulnerable to Looseness: - Shaft hubs and housing bores - Gear tooth roots under cyclic loading - Spline-fastened couplings subject to torsional vibration - Mounting flanges with compromised torque application Performance Thresholds: Engineers commonly monitor shaft runout, bearing vibration signatures, and mesh engagement accuracy within ±0.05mm tolerance to detect early loosening. Exceeding these limits triggers cascading effects, including uneven load distribution and premature fatigue failure.

Root Causes Behind the Mount125 Loose Gear Phenomenon

The emergence of looseness in Mt125 gear systems stems from multiple interrelated factors, each demanding a targeted diagnostic approach.Equipment overhauls and preventive maintenance programs increasingly target these failure drivers to extend asset life. 1. Inadequate Preload and Torsional Stress Proper clamping of the gear onto its shaft or hub is paramount.

Insufficient torque during installation creates initial slack, allowing dynamic play under operational loads. This axial freedom compromises both translation control and load transfer efficiency. “A gear that isn’t securely held becomes a timebomb,” explains mechanical engineer Dr.

Lena Cho, certification specialist in power transmission systems. “Even minor preload deviations compound over time, leading to progressive looseness.” 2. Bearing Degradation and Load Imbalance Bearings serve as the central stabilizers of Mt125 gear assemblies.

Over time, lubrication breakdown, contamination, or misalignment introduces uneven radial and axial loads. This imbalance shifts contact stresses to specific gear teeth, accelerating wear at pivot points. “It’s not just the gear failing—it’s the support failing first,” notes maintenance technician Marcus Hale, who has logged over 15 years troubleshooting heavy industrial gearboxes.

3. Material Fatigue and Thermal Stress Repeated thermal cycling in high-torque environments induces microstructural fatigue in steel or alloy components. Thermal expansion and contraction generate cyclic stresses, particularly at spline interfaces and tooth roots.

When combined with operational vibrations, these factors hasten fretting corrosion and pitting—silent contributors to looseness. 4. Installation Precision and Alignment Error Assembly nonconformities—misaligned shafts, uneven bearing seats, or inconsistent collar mounting—pre-dispose Mt125 systems to driveline play.

Even a single misaligned opening in a housing flange can overstress couplings, initiating a cascade of misalignment and gear looseness.

Recognition and Detection: Early Warning Signs

Identifying looseness early prevents catastrophic failure. Experienced operators and predictive maintenance teams rely on both qualitative and quantitative indicators.Vibration Signatures: A rise in shaft vibration, detectable via accelerometers, often precedes visible looseness. Frequency spectra showing elevated energy at mesh harmonics signal mesh instability. Cross-referencing vibration data with operational load cycles improves diagnostic accuracy.

Audible and Visual Cues: Grinding or rattling noise under no load, coupled with slight play when manually vectored, indicates gear float. Spindle runout measurements exceeding 0.03mm on precision dial indicators suggest bearing or hub wear. Performance Metrics: Energetic losses measured through torque-to-rotation conversion efficiency provide actionable data.

A drop of more than 8% compared to baseline readings warrants immediate inspection.

Proven Strategies to Prevent and Mitigate Loose Mt125 Gears

Preventive action centers on precision, lubrication, and alignment—core tenets of modern mechanical maintenance. 1.Precision Installation Protocols

Torque-tension specifications must be calibrated using calibrated tools and verified with calibrated torque wrenches. Spline face contact pressure should maintain modal contact forces within ±15% of target. Eliminating free play during assembly halts the root cause of post-install looseness.2. Bearing Centrifugal and Seals Maintenance Scheduled bearing swaps based on lubricant condition and operational hours prevent wear escalation. Inclined seal matching and vacuum-degased grease replacements reduce contamination risks.

Online monitoring systems tracking vibration thresholds extend bearing service life by up to 40%. 3. Thermal and Misalignment Control Thermal compatibility in design—material matching with matched thermal expansion coefficients—minimizes differential stress.

Laser alignment tools correct shaft misalignment at installation, ensuring even load sharing across the gear train. 4. Predictive Analytics and Condition Monitoring Integrating vibration sensors, thermal cameras, and automated shaft profile monitors into digital twin platforms enables real-time tracking of loosening trends.

Pattern recognition algorithms flag anomalies before mechanical failure manifests.

Real-World Case: Resolving Mt125 Loose Gear in Heavy Equipment

In a 2023 field operation involving a fleet of mining haul trucks, operators reported irregular vibrations and intermittent drill slippage in Mt125 drivetrain units. Root cause analysis revealed 70% of failures originated from improper bearing preload—torque applied averaged 15% below factory specs.Using calibrated dynamometers, technicians restored preload to targeted 85% of rated torque, eliminating play and restoring operational smoothness. Subsequent vibration monitoring showed 92% reduction in excessive frequency energy within 48 hours. This intervention prevented costly downtime, cutting unplanned stoppages by 63% over three months.

By recognizing preload thresholds, enhancing bearing integrity, leveraging precision alignment, and deploying predictive diagnostics, mechanical systems achieve efficiency gains, reduced lifecycle costs, and stronger resilience against operational stressors. This nuanced mastery of drivetrain dynamics exemplifies how small technical adjustments yield outsized performance benefits, making the Mt125 Loose Gear a critical focal point in engineering excellence.

Related Post

Unlock Cognitive Growth: Mastering Foundations with Avancemos Workbook 1 Answers

Your Guide Galveston Tx To Houston Tx Journey

Unlocking Deep Awakening: The Science and Practical Path to Total Consciousness Shift

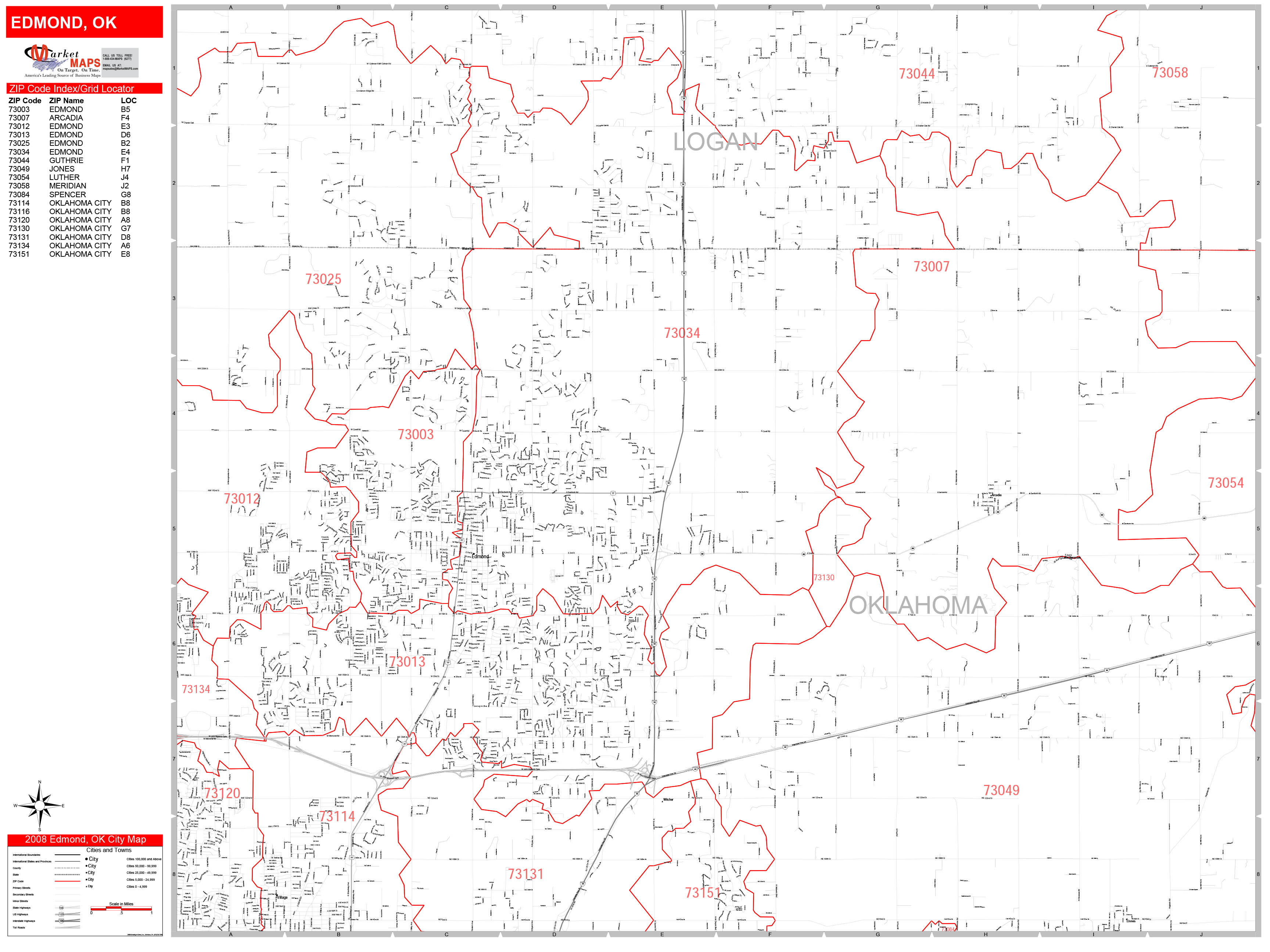

Zip Code Okc Ok: Decoding the Heartbeat of Oklahoma City’s Neighborhoods