Kpa to Psi: Quantum Revelations Bridging Design, Safety, and Measurement Across Industries

Kpa to Psi: Quantum Revelations Bridging Design, Safety, and Measurement Across Industries

The biomechanical parabolic relationship between kilopascal (kPa) and pounds per square inch (psi) is emerging as a pivotal conversion point in engineering, medical device development, construction safety, and beyond. Though distinct in unit origin—kPa rooted in the International System of Units and psi in the imperial system—they govern pressure and force with profound implications in real-world applications. Understanding their precise conversion isn’t merely an academic exercise; it’s a functional bridge enabling global technical collaboration, regulatory compliance, and innovation.

This deep dive unpacks how kPa to psi conversion underpins critical fields, from hospital ventilators to industrial pressure vessels, illuminating the silent but essential role metrology plays in modern progress.

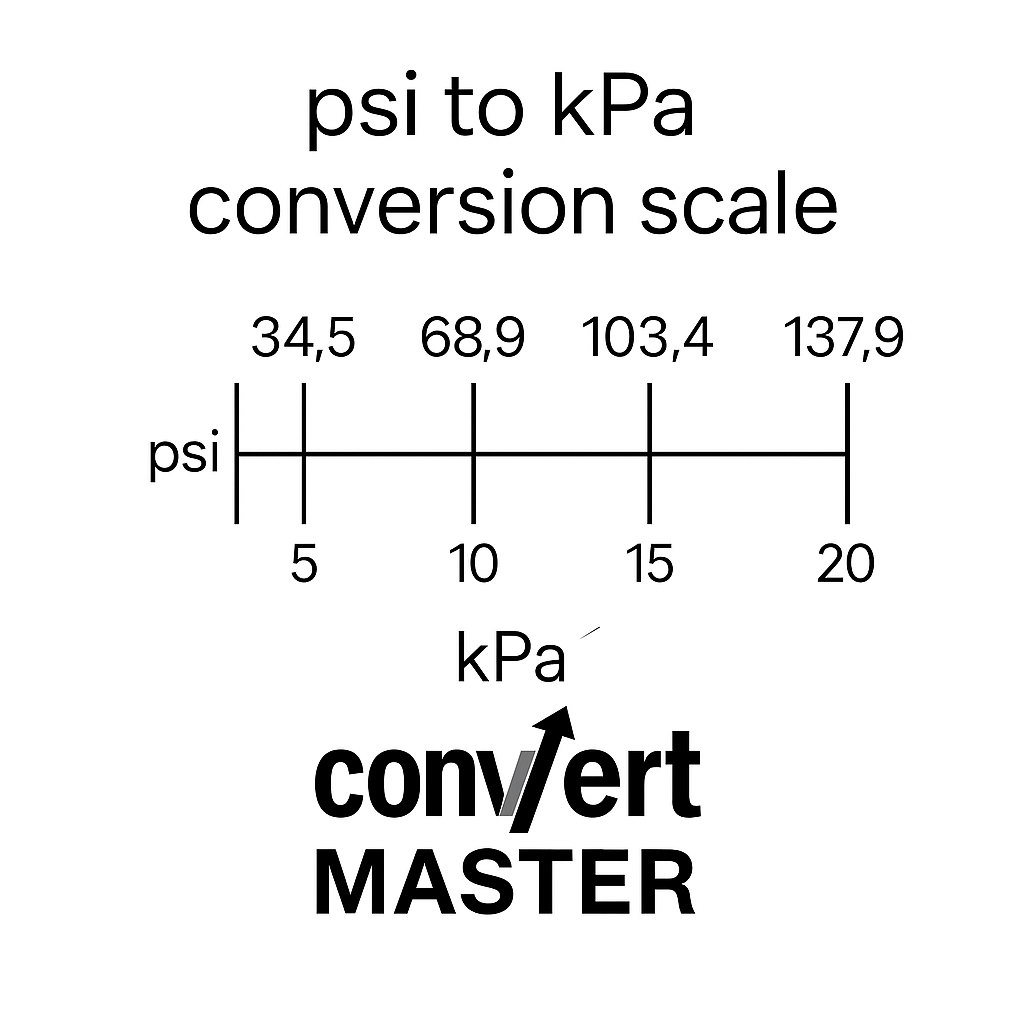

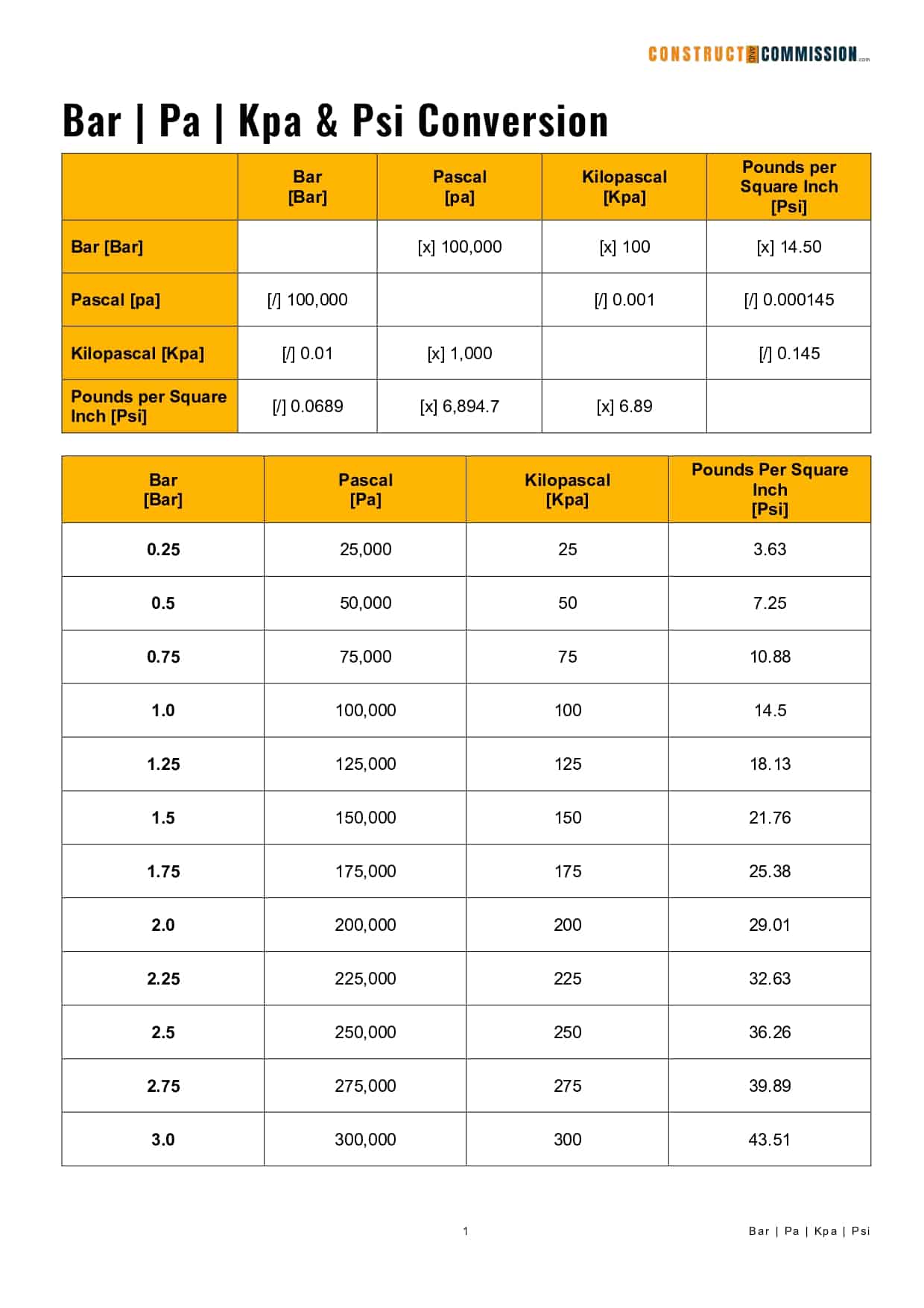

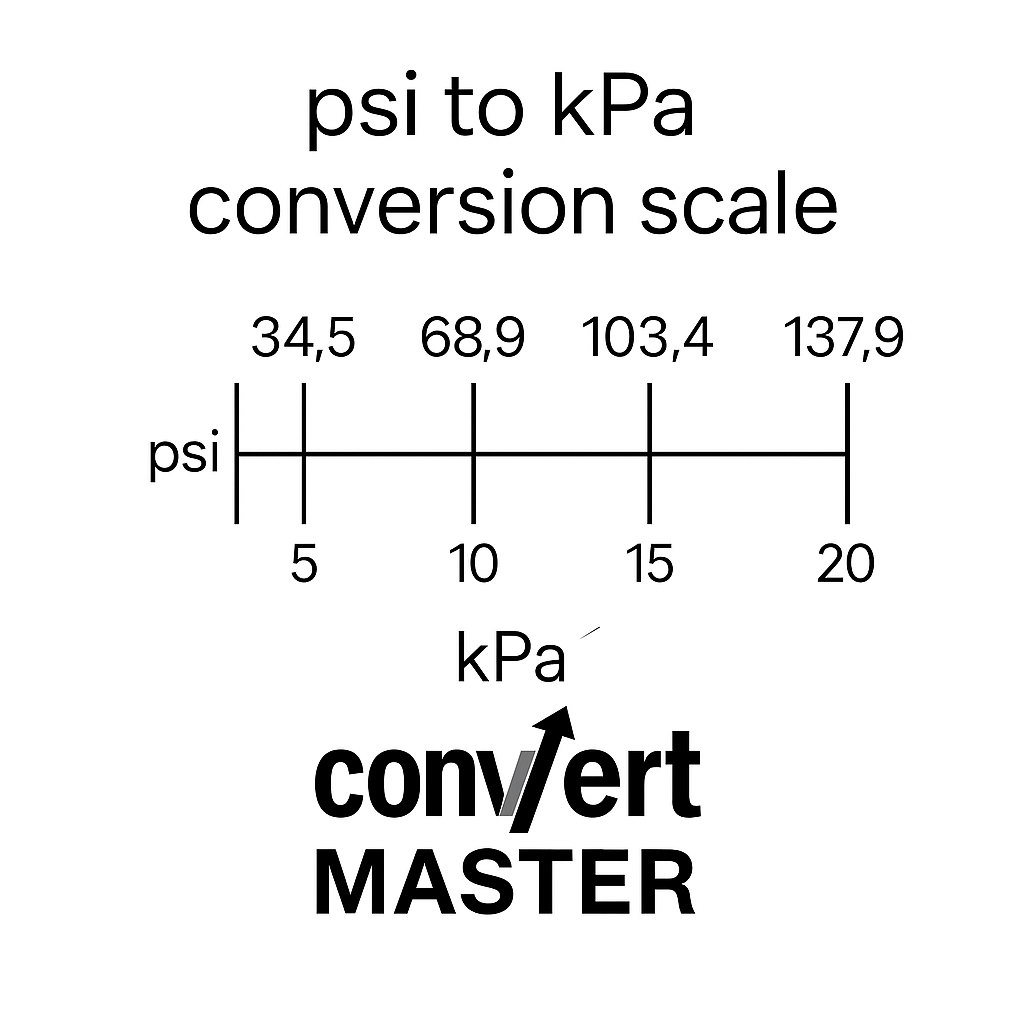

At the core, kPa and psi represent pressure—force applied per unit area. One kilopascal equals 0.1450377 psi, a coefficient derived from the difference between metric and English systems.

Specifically, 1 kPa = 14.5 psi when rounded for practical engineering use. This conversion, seemingly mathematical, carries life-or-death consequences in contexts where precision is non-negotiable. Medical ventilators, for instance, rely on controlled pressure delivery measured in kPa in Europe, while U.S.-based manufacturers often specify constraints in psi, necessitating exact translation to ensure patient safety and device interoperability.

Engineering Precision: The Critical Role in Mechanical Systems

In the realm of mechanical engineering, pressure often dictates performance, durability, and reliability. KiloPascal and pound-per-square-inch serve as universal currencies in system design—whether evaluating compressor outputs, hydraulic lines, or pressure-regulating valves. Consider industrial pneumatic systems where actuators must deliver precise force across global supply chains.A mismatch in pressure units between engineering blueprints and on-site instrumentation can trigger inefficiencies, equipment failure, or even catastrophic ruptures. For example, hydraulic systems in heavy machinery are frequently rated in psi in North America, while European specifications increasingly use kPa. When integrating components from multinational suppliers, engineers must apply the conversion factor: 1 kPa ≈ 14.5 psi.

“Even a 5% error in pressure translation can result in overloading a cylinder by several hundred kilograms,” cautions Dr. Elena Marquez, a mechanical standards specialist. “This isn’t just a math problem—it’s a technical safeguard.” This conversion underpins safety protocols as well.

Pressure relief valves, critical for preventing explosions, operate within calibrated thresholds. International standards organizations such as ISO and ASTM recognize the need for dual-unit validation, requiring documentation that reflects either measurement without ambiguity. “Engineers can’t afford to select components blindly,” notes Marquez.

“Using the exact psi or kPa ensures clear communication across design, manufacturing, and regulatory checkpoints.”

Medical Innovation: Life-Sustaining Accuracy in Critical Care

In healthcare, the conversion between kPa and psi is not abstract—it’s a matter of patient outcomes. Respiratory devices, such as ventilators and anesthesia machines, depend on precise pressure control to support breathing, deliver medications, and maintain optimal gas exchange. European and global settings rely predominantly on kilopascal, yet many U.S.medical devices historically used psi. As global device trade expands, consistent pressure metrics are paramount. Consider a patient’s airway set point, often maintained between 10 and 20 kPa.

In metric documents, this translates to approximately 145–290 psi—a range that directly impacts oxygen delivery and lung compliance. If a device manual incorrectly specifies a pressure in psi but the intended unit is kPa, or vice versa, the consequences could be life-threatening. “One misread conversion during device calibration could reduce therapeutic efficacy or even cause lung injury,” warns Dr.

Samuel Okoye, a biomedical engineer specializing in global device safety. Battery-operated ventilators deployed in remote clinics must function across diverse systems, requiring firmware calibrated in metric pressure. Manufacturers now embed dual-unit displays, automatically converting pressure values between kPa and psi in real time.

“Technology should transcend unit systems, not hinge on flawed translations,” Okoye insists. “A unified approach to pressure measurement saves lives.”

Construction and Infrastructure: Safety, Compliance, and Material Integrity

Beyond industry and medicine, the kilopascal-to-psi conversion plays a decisive role in civil engineering and construction. Structural design—especially pressure vessels, pneumatic lifts, and building ventilation systems—demands exact pressure specifications to meet safety codes.In the UK and most EU nations, pressure ratings are published in kPa, whereas U.S. standards often reference psi. A misalignment between these units can compromise structural integrity and regulatory approval.

High-rise buildings use pneumatic elevators and HVAC systems where pressure differentials influence energy efficiency and occupant comfort. “When specifying impulse panels or pressure switches, engineers must account for regional unit choices,” explains structural consultant Maya Tran. “A 2.5 MPa pressure chamber—roughly 362 psi—translates to significant design load factors.

Related Post

Need to Convert 10 KPa to PSI? Here’s the Fast & Accurate Guide You Can’t Ignore

Dede Blanchard Murder Scene: A Deep Dive Into the Shocking Case That Shook a Community

Was Ronaldo The Number 9 At Real Madrid? Unraveling His Iconic Role Beyond The Stats

Unlocking Nomor.Se: The Game-Changer Advancing Digital Identity and Secure Communication