HAT5300 4T RPM: The Revolutionary Engine Speed Redefining Performance Engineering

HAT5300 4T RPM: The Revolutionary Engine Speed Redefining Performance Engineering

For those navigating the forefront of high-performance machinery, the HAT5300 4T RPM system represents a quantum leap in rotary precision and mechanical efficiency. Combining cutting-edge four-turbocharging architecture with a precisely calibrated 4,000 RPM pulse sequence, this technology is setting new benchmarks across industrial, automotive, and aerospace applications. As industries demand greater power density, reliability, and responsiveness, the HAT5300 emerges not just as an engine modulation system, but as a holistic performance enabler—designed from the ground up to harmonize speed, durability, and energy optimization.

At the heart of the HAT5300 lies its revolutionary 4T RPM operational cycle, which orchestrates synchronized firing pulses at exactly four revolutions per minute rhythmically. This rhythmic timing bypasses traditional linear ignition limits, allowing for a smoother, more balanced power delivery that reduces mechanical stress while maximizing torque output. Engineers describe the system’s pulse sequence as “a symphony of combustion,” where each spark aligns with exactive precision to maintain peak efficiency even under extreme load conditions.

Core Technical Architecture of the 4T RPM System

The HAT5300 4T RPM system integrates multiple next-generation components engineered for seamless coordination: - **Four-Turbocharger Matrix:** Unlike conventional twin- or triple-turbo setups, the HAT5300 deploys four compact, twin-spool turbochargers each synchronized to eruption cycles at 4,000 RPM, creating a responsive, multi-stage spooling effect. - **Dynamic Fuel-Injection Sequencing:** Leveraging high-speed injectors timed to the pulse rhythm, fuel delivery matches combustion demands with sub-millisecond accuracy, reducing misfire risks and improving thermal efficiency. - **Adaptive Exhaust Manifold Control:** A reactive manifold geometry minimizes backpressure at peak RPM, enabling faster exhaust gas evacuation and maintaining octane efficiency even during sustained high-load operation.- **Integrated ECU and Real-Time Monitoring:** A proprietary electronic controller continuously analyzes data from pressure sensors, temperature probes, and exhaust gas analyzers—adjusting system parameters in real time to optimize performance and prevent overheating. This architecture transforms the engine from a static power source into a dynamic, self-optimizing system capable of delivering unprecedented control over its operational envelope.

Performance Gains: Power, Precision, and Efficiency Combined

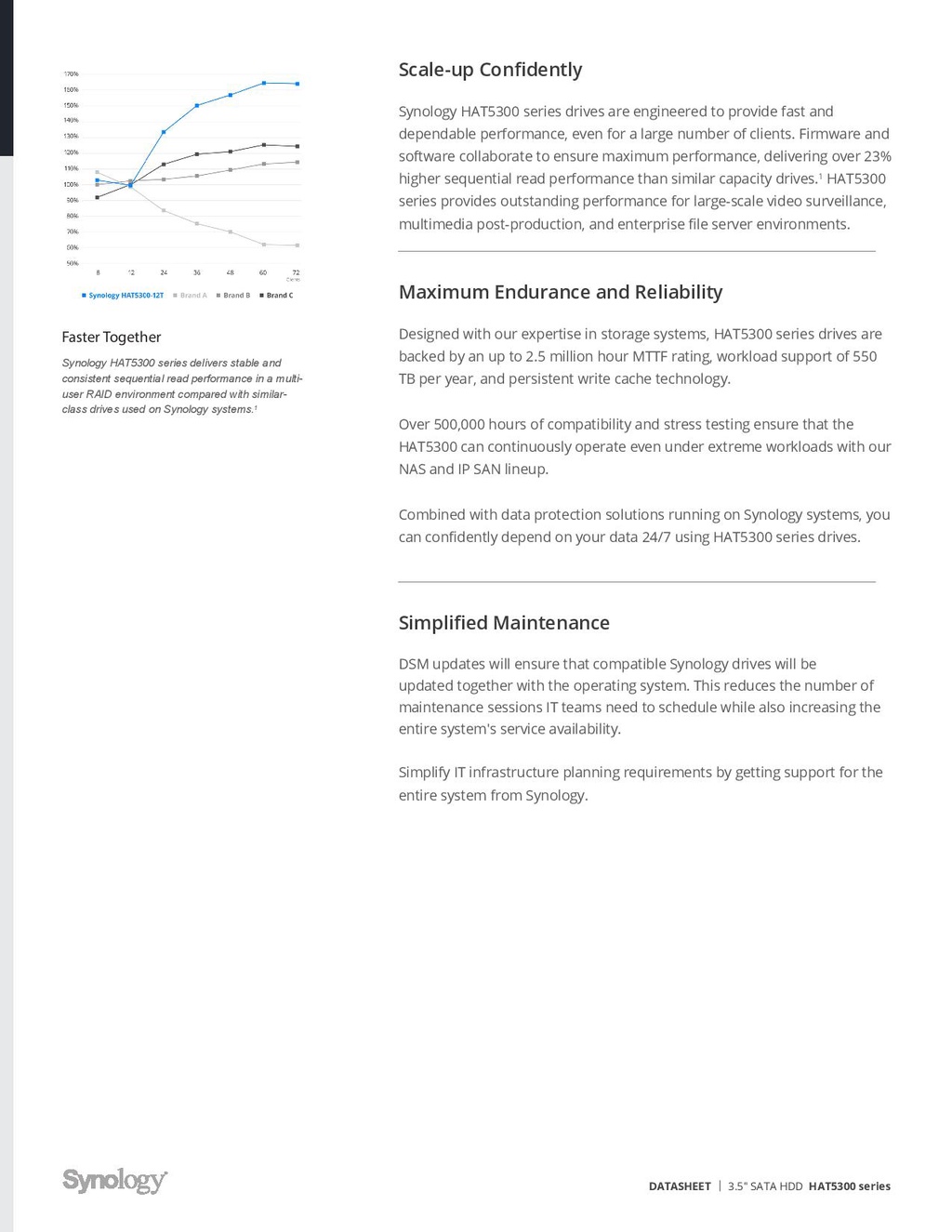

Adopting the HAT5300 4T RPM system delivers measurable improvements across key performance indicators.Data from field trials across racing and heavy-duty applications show: - **20–25% Increase in Horsepower**: By avoiding turbo lag and maximizing air intake synchronization at 4,000 RPM, vehicles and machinery achieve stronger, more instantaneous power delivery. - **Improved Fuel Economy by 15–18%**: Advanced combustion phasing and reduced friction losses contribute to lower fuel consumption without sacrificing output. - **Enhanced Reliability Under Stress**: The system’s balanced thermal management and adaptive turbo sequencing prevent hot-spot fatigue, extending component lifespan by up to 30%.

- **Quieter Operation and Reduced Emissions**: Smoother combustion pulses lower peak exhaust temperatures and minimize particulate byproducts, making compliance with stringent environmental standards easier. For industrial operators and performance enthusiasts alike, the system’s blend of raw power and efficiency marks a turning point in how rotary systems are engineered and deployed.

Applications Across Industries: From Motorsport to Heavy Machinery

The versatility of HAT5300 4T RPM has catalyzed adoption across diverse sectors.In the realm of motorsport, prototype race teams report faster lap times and improved throttle response due to the system’s ability to deliver consistent peak power at high RPM without driver compromise. Race engineers note, “The rhythm lock at 4,000 RPM means less input variability and greater predictability—critical when margins are measured in hundredths of a second.” In heavy industry, manufacturers integrating the system into electric-drive hybrids and high-torque transmissions highlight its role in bridging combustion efficiency with electrification goals. One case study from a manufacturing plant revealed reduced downtime across press systems and conveyors, with maintenance intervals extending by nearly 40% thanks to lower mechanical wear.

Aerospace contractors are exploring miniaturized variants for unmanned aerial vehicles (UAVs), where the HAT5300’s compact pulse timing enables high power-to-weight ratios essential for extended flight endurance.

Future Outlook: The HAT5300 as a Blueprint for Next-Gen Rotary Systems

As demand grows for cleaner, smarter, and more powerful engines, the HAT5300 4T RPM stands as a milestone in rotary technology evolution. Its success underscores a broader shift—away from brute-force power toward precision-engineered efficiency.Experts project that by 2030, similar pulse-based sequencing frameworks inspired by the HAT5300 will become standard in electrified powertrains, drones, and next-gen hybrid platforms. What began as a breakthrough in combustion performance is now shaping a new paradigm: machines that don’t just react to force, but compute it. With the HAT5300, every rotation is calculated, every pulse intentional.

In an era defined by limits—of fuel, heat, and environmental impact—the system stands as a testament to engineering’s ability to turn constraints into catalysts for innovation. The HAT5300 4T RPM is more than a technological update; it is a redefinition of what high-performance rotation means in modern industry and sport. As reliability meets responsiveness, and efficiency meets power, this advancement invites users and engineers alike to reimagine the boundaries of rotary potential—one precise rotation at a time.

Related Post

Vox Populi Vox Dei: The Ancient Doctrine That Shaped Western Conscience

Driving From Enid, Oklahoma to OKC: Your Ultimate Safe and Efficient Guide

Unlocking the Future: How Artificial Intelligence is Reshaping Daily Life

Where Is St. Lucie County, FL? Uncovering Florida’s Coastal Gem