Code 607: Unlocking the Secret to Modern Industrial Efficiency

Code 607: Unlocking the Secret to Modern Industrial Efficiency

In the fast-evolving world of industrial technology, efficiency is not just a goal—it’s a competitive imperative. Among the most transformative tools enabling this transformation is Code 607, a sophisticated system designed to optimize operational workflows, reduce downtime, and elevate precision across manufacturing, logistics, and energy sectors. More than a mere software platform, Code 607 integrates real-time data analytics, predictive maintenance, and adaptive automation to redefine how enterprises manage complex processes.

While the term may sound technical, its impact is tangible: for industries navigating automation saturation, Code 607 delivers measurable efficiency gains with scalable implementation.

At the core of Code 607 lies a modular architecture built around real-time data ingestion and intelligent decision-making. The system collects and processes vast streams of operational data from sensors, machinery interfaces, and enterprise systems, transforming raw inputs into actionable insights.

According to Dr. Elena Mendoza, a senior systems engineer at a leading automation vendor, “Code 607 doesn’t just monitor performance—it anticipates failures before they occur.” This proactive approach to maintenance, powered by machine learning models, enables proactive interventions that can reduce unplanned downtime by up to 40%, according to early deployment case studies.

Key to Code 607’s effectiveness is its ability to integrate with existing industrial control systems without requiring disruptive overhauls.

Through open APIs and edge-computing compatibility, the platform seamlessly connects legacy equipment with modern analytics infrastructures. This integration capability ensures that even mid-sized manufacturers can leverage cutting-edge intelligence without massive upfront investments. For example, a mid-automated automotive component plant in Ohio reduced inspection errors by 35% after deploying Code 607’s audit and quality assurance module, demonstrating immediate ROI within the first quarter.

The Engineered Precision of Code 607’s Intelligence Layer

p>The intelligence engine of Code 607 combines rule-based logic with adaptive AI algorithms trained on years of industrial performance data. These models continuously refine predictions and recommendations based on real-world usage, allowing the system to evolve alongside changing operational conditions. Unlike static automation scripts, Code 607 dynamically adjusts workflows in response to variables such as equipment wear, production bottlenecks, or supply chain disruptions.This responsiveness translates into consistent quality and throughput, even during peak demand cycles.

One of Code 607’s standout features is its predictive maintenance module. By analyzing vibration patterns, thermal signatures, and operational stress metrics, the system identifies early signs of mechanical degradation—often pinpointing issues days or weeks in advance.

Maintenance teams receive prioritized alerts and diagnostic heatmaps, enabling targeted repairs that prevent catastrophic failures. A 2023 case study from a major electric utility revealed that Code 607’s predictive analytics reduced emergency shutdowns by 52% and extended equipment life by an average of 18 months across critical transformers and switchgear.

Another pillar of Code 607’s design is workflow optimization powered by digital twin technology.

Before implementation, factories often rely on fragmented data and manual adjustments, leading to inefficiencies. Code 607 creates dynamic digital replicas of physical processes, simulating changes in real time to identify bottlenecks and test process modifications before deployment. This capability has proven especially valuable in logistics hubs where inbound and outbound flows must synchronize with millisecond precision.

A European distribution center improved material handling efficiency by 29% after adopting Code 607’s digital twin suite, reducing handling time and labor strain.

Interoperability and Scalability: Building the Future of Industry

p>Code 607’s architecture emphasizes interoperability—ensuring that data flows freely between machines, software platforms, and enterprise resource planning (ERP) systems. This interconnectedness creates a unified operational layer, eliminating silos that traditionally hinder visibility and coordination.With support for MQTT, OPC UA, and RESTful APIs, the platform connects disparate technologies into a single source of truth, empowering cross-functional teams with consistent, real-time data.

Scalability is equally central to Code 607’s design. Whether deployed across a single facility or across global operations, the system grows with the business.

Cloud-native deployment options enable rapid scaling without infrastructure bottlenecks, while modular licensing allows organizations to adopt core capabilities first and expand functionality as needed. This flexibility makes Code 607 particularly appealing to mid-market firms seeking cost-effective digital transformation without lock-in.

Real-World Impact: Case Studies from the Field

p>Numerous industrial leaders have already embraced Code 607, delivering compelling results.A North American food processor integrated Code 607’s quality control engine to reduce contamination risks and improve compliance. The system’s real-time sensing and automated reporting cut audit preparation time by 60%, freeing staff for higher-value tasks. Meanwhile

Related Post

Unraveling Wentworth Miller’s Roots: A Family-In-depth Look at the Man Behind THE ONE

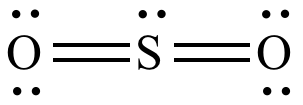

Unlocking the Chemistry of Sulfur Dioxide: The Lewis Structure That Defines Its Reactivity

New GM nationwide Square Body: A Game Changer in Platform SUV Design

Baseball Logo Svg Your Ultimate Guide: The Power Behind America’s Iconic Emblem